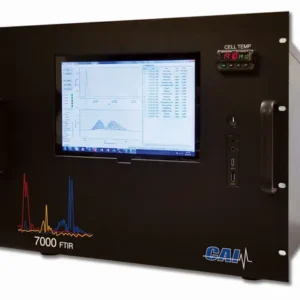

The 7500Z and 7600Z Series Infrared (IR) Analyzers are capable of detecting up to four chosen, individual IR absorbing components (i.e. CO, CO2, CH4, SO2, NO or NOX with external converter) on a continuous basis. Conveniently packaged in either a 19” rack mount (Model 7500ZA / 7600ZA) or NEMA-4 wall mount enclosure (Model 7500ZB / 7600ZB), the analyzer can also be supplied with an oxygen sensor, providing the operator with space saving, five in one, cost-effective design. The NEMA-4 enclosure can be purged to meet Class I, Div 1 (Zone 1) or Class I, Div 2 (Zone 2) hazardous area installation requirements.

- Brand

- Overview

- Features

- Specifications

Brand

Teledyne Analytical TAI

Overview

Twin Detector

A high-sensitivity mass flow type twin detector is utilized for infrared measurements. By using a single beam, single path design in conjunction with a serial dual-layer transmission detector, the 7500Z Series delivers long-term, drift-free performance. The 7600Z Series achieves greater performance through an internal sample-switching system which serves to cancel zero drift.

Paramagnetic/Electrochemical Sensor

The oxygen concentration in the sample gas can be detected by either a built-in paramagnetic sensor or electrochemical sensor. The concentration of the desired gas is displayed on a large, easy-to-read back-lit LCD. The user interface is very intuitive and the menu/mode selection buttons, which are readily accessible, provide the operator with dynamic control and extensive diagnostic capabilities.

Available Analysis Gases and Ranges

| Gases | Ranges |

| NO | 0-50 ppm to 0-5,000 ppm |

| SO2 | 0-50 ppm to 0-10% |

| CO2 | 0-50 ppm to 0-25% |

| CO | 0-50 ppm to 0-5,000 ppm |

| CH4 | Not Available |

| O2 (built in fuel cell) | 0-10% to 0-25% |

| O2 (built in paramagnetic) | 0-5% to 0-100% |

Features

- Steel case for indoor installation

- Wetted materials: 304SS sample cell, chloroprene rubber seals

- CaF2 optical windows, Tygon/Teflon/Polypropylene tubing

- 1/4″ NPT gas connections (1/4″ RC optional)

- 1 or 2 ranges per gas with auto-ranging and remote range selection (optional) capabilities

- O2 correction calculation available

- Integral auto-calibration and remote calibration functionality with solenoid valves to be provided by end user (integral auto-calibration valves available as an option)

- Reading averaging capability available

- Integral compensation for atmospheric pressure changes available

- CE marked, conforms to Low Voltage Directive and EMI/RFI standards

Specifications

| Repeatability | ± 0.5% of full scale |

| Linearity | 1% of full scale prior to atmospheric correction (option) |

| Drift | Zero: ± 0.5% of full scale/week (measureable component of NDIR) ± 2% of full scale/week (O2 analyzer) Span: ± 2% of full scale/week |

| Response Time | 30 seconds or better Response interval may be changed depending on timing of the switching gas by sample switching operation (Td = 5-20 seconds) |

| Temperature | 23° to 113°F (-5° to 45°C) |

| Pressure | Less than 1.5 PSIG, went to atmospheric pressure |

| Sample Flow | 1.0 SCFH (0.5 SLPM) |

| Utility Gases | N2 or Air (CO2 -free for CO2 unit) 2 SCFH (1 SLPM) |

| Power | 100-240 VAC, 50/60 Hz (100 VA Max) |

| Dimensions | Rack Mount: 19″L x 5.22″H x 15.04″D (48.3 x 13.3 x 38.2 cm) Approximately 29 lbs (13.15 kg) Wall Mount: 24″L x 24″H x 12″D (61.0 x 61.0 x 30.5 cm) Approximately 60 lbs (27.22 kg) |

| Included I/O | 4-20 mA (isolated) analog per measurement (or 0-1 VDC optional) RS-485 MODBUS® RTU™ half-duplex serial communications 1 x system alarm, Form-C type, rated 1A / 24 VDC 1 x concentration alarms, Form-C type, rated 1A / 24 VDC Range identification contact, Form-A type |