Offers excellent performance for multigas measurements in dry sampling, including HCl, HF, NO, NO2, N2O, SO2, CO, CH4, TOC, CO2 and O2.

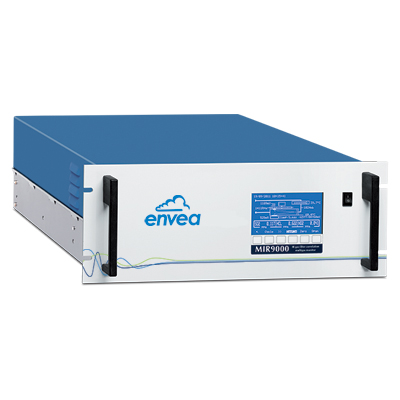

Multi-Gas NDIR-GFC analyzer (Non-Dispersive Infrared Gas Filter Correlation) measuring up to ten gases simultaneously, including Nitrogen Oxide (NO), Nitrogen Dioxide (NO2), Sulphur Dioxide (SO2), Carbon Monoxide (CO), even Hydrogen Chloride (HCl) and Hydrogen Fluoride (HF).

Over 4,000 MIR9000 gas CEMS monitors are installed worldwide for process optimization and environmental compliance

- Brand

- FEATURES & BENEFITS

- MAIN APPLICATIONS

- TECHNICAL SPECIFICATIONS

- TECHNICAL DATA

- APPROVALS & CERTIFICATIONS

FEATURES & BENEFITS

- The MIR 9000 is the most popular ENVEA extractive multi-gas analyzer, being used in all type of industries and compliant with all regulations worldwide

- Designed to measure dry & corrosive samples

- Fast & simultaneous measurements of up to 10 gases

- Dry basis measurement

- Automatic cross interference correction

- Ideally used with SEC® box permeation sample drying technology and non-heated sample lines for cost effective operations

- Intrinsic security with residual H2O measurement

- Built-in paramagnetic cell for O2 monitoring

- The MIR-9000 is either available in a 19″ rack or wall mount enclosure (Tight box version)

MAIN APPLICATIONS

- Stack emission compliance for Municipal and Hazardous Waste Incinerators

- Cogeneration, Gas Turbines (for ultra-low NOx measurements we recommend the use of the model MIR 9000 CLD )

- Industrial Boilers and Furnaces

- Power & Combustion

- Cement Kilns, Glass, Chemical & Petrochemical Plants

- Efficiency control for DeNOx systems to guarantee their proper performance

- For pre and post catalyst SO2 monitoring (DeSOx unit process control) we recommend the use of the model MIR 9000ASD

TECHNICAL SPECIFICATIONS

| MEASURABLE PARAMETERS | ||||

|---|---|---|---|---|

| Pollutant | Range | |||

| HCI | 0-15 / 5000 | |||

| HF | 0-20 / 300 | |||

| NO | 0-100 / 5000 | |||

| NO2 | 0-100 / 1000 | |||

| N2O | 0-20 / 1000 | |||

| NOx | 0-200 / 5000 | |||

| SO2 | 0-75 / 5000 | |||

| CO | 0-75 / 1000 | |||

| CH4 | 0-10 / 1000 | |||

| THC | 0-50 / 5000 | |||

| CO2(%) | 0-10 / 100 | |||

| O2(%) | 0-10 / 25 | |||

Other ranges available upon request

| TECHNICAL SPECIFICATIONS | |

|---|---|

| QAL1 to EN 15267-3 certified | YES |

| US EPA compliance | YES |

| Sampling technology | Cold/Dry Extraction |

| Sample transfert | non heated polytube |

| back flush function | YES |

| span injection | YES on analyser or at sample point |

| Built-In O2 option | YES |

| Serial link communication | RS232 / RS422 |

| Other Communication | Ethernet |

| Analogue OUTPUTS | Optional |

| Analogue INPUTS | Optional |

| Dimensions (mm) | • Tight box version: 200 x 400 x 600 (D x W x H) • 19” rack version: 490 x 483 x 177 (D x W x H) |

TECHNICAL DATA

Complete CEMS would normally comprise of:

- MCERTS & TÜV QAL 1 certified MIR-9000 multi-gas emissions analyzer

- Graphite 52M FID (If working to EN12619 VOC standard)

- Sample extraction and conditioning probe (with or without integrated temperature, pressure and flow measurement)

- SEC® sampling system (permeation based) or gas cooler

- Sample lines

- Automatic calibration units (TIG)

- Instrument air drying system (MDS)

- Multiplexing system (MVS) for dual redundancy*

- Rack cabinet, cubicle or shelter integration

- MCERTs Certified ENVEA WEX Data acquisition & management system

*Dual Redundancy System

Under the IED, the maximum period allowed for any one episode of abatement or equipment failure must not exceed four hours. Additionally, the total allowance period for a year must not exceed sixty hours.

The ENVEA duplex philosophy has therefore been specifically developed to assist you in complying with IED by reducing downtime, maximising availability and ensuring you achieve a sound return on your investment.

APPROVALS & CERTIFICATIONS

The MIR 9000 multi-gas CEMS offer compliance with EU Regulation IED (WID / LCPD / MCP directive) BREF Incineration, US EPA (40 CFR 60 & 75)

- QAL 1 certified by the TÜV and the MCERTs to EN 15267

- QAL3 compliance as defined by EN 14181

- U.S. EPA approved as compliant with 40 CFR 60 ET 75