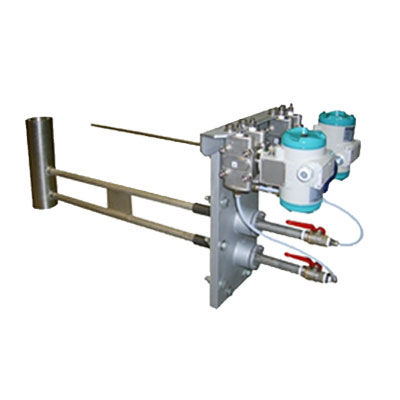

Flue gas flowmeter for continuous measurement of gas velocity, temperature and pressure in exhaust gas ducts (chimneys or flue pipes). Micro-Venturi technology.

The StackFlow 100 is a compact flowmeter for continuous measurement of velocity, temperature and static pressure in exhaust gas ducts ( stacks or flue gas ducts) using the Micro-Venturi technology. From these measurements, StackFlow 100 allows to determine the flue gas volume flow rate via an additional calculation element which is either performed by an ENVEA controller or directly by the CEMS cabinet’s data acquisition station. This data is used to calculate the mass flows of the pollutants released (dust, SO2, NOx…).

- Brand

- FEATURES & BENEFITS

- MAIN APPLICATIONS

- TECHNICAL SPECIFICATIONS

- TECHNICAL DATA

- APPROVALS & CERTIFICATIONS

FEATURES & BENEFITS

- A single connection port integrated into the NFX flange of the gas sampling ENVEA LCPD box

- Highly accurate and continuous measurement of gas velocity, temperature and pressure (DTP measurement)

- Robust construction, resistant to harsh industrial environments

- Clogging with no effect on the measurement, no need for backflushing

- Compact solution with integrated pressure and temperature sensors

- Measuring range: 3-30m/s with an accuracy of less than 10% above 5m/s

MAIN APPLICATIONS

- Combustion plants

- Urban heating

- Industrial chimneys (before or after treatment)

- Process measurements in metallurgy, chemistry, mineral industry

- Chemicals (eg Refinery / Rubber)

- Power Generation Plants (eg Coal/Biomass)

TECHNICAL SPECIFICATIONS

| TECHNICAL SPECIFICATIONS | |

|---|---|

| Measured parameters | Flue-gas velocity |

| Technology | Micro-venturi |

| Measurement/Monitoring capability | 3 – 30 m/s* |

| Stack/Duct diameter suitability | 300mm up to 1,5m |

| Flue gas temperature | up to 400°C |

| Baghouse | YES |

| Cartridge Filter | YES |

| Ceramic Filter | YES |

| Coalescent Filter | YES |

| Cyclone | YES |

| Electrostatic Precipitator (ESP) | YES |

| Wet Electrostatic Precipitator (WESP) | YES |

| Wet Scrubber | YES |

| Sensor variants | Stainless Steel |

| QA checks | NO |

TECHNICAL DATA

| TECHNICAL DATA | |

|---|---|

| Measurement capability | 3 – 30 m/s |

| Resolution | 0.2 m/s |

| Sensor Variants | 316 Stainless Steel |

| Stack Temperature Ranges | 400°C max |

| Functionality and QA Checks | Manual reference checks |

| Data Output | 3 outputs 4-20 mA not isolated RS485 (Modbus) output to Controller |

| Mounting flange | NFX 44-052 |

| Enclosure Protection Rating | IP65 |

APPROVALS & CERTIFICATIONS

- Compliance with the MCP directive