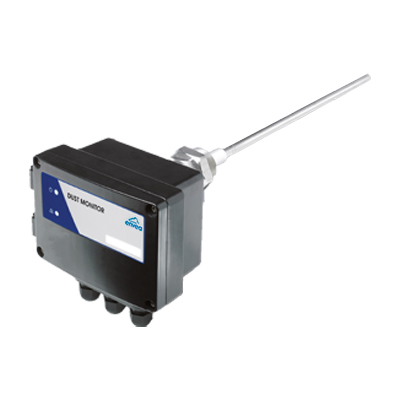

Using the patented ElectroDynamic™ technology the DUST MONITOR 210 is a Filter Leak Monitor suited to filter control applications after fabric dust filter type (baghouse) arrestment plant.

The instrument offers a rugged and reliable filter leak monitoring capability. Options available for UKEX/ ATEX /IECEx explosive zone and stand-alone or controlled unit systems.

- Brand

- FEATURES & BENEFITS

- MAIN APPLICATIONS

- TECHNICAL SPECIFICATIONS

- TECHNICAL DATA

- APPROVALS & CERTIFICATIONS

FEATURES & BENEFITS

- High-quality leak response with sufficient dynamic range and time response to track emissions from single and multi-compartment pulse cleaned bag filters

- System self-checks (drift checks) to validate measurement integrity including automatic Zero and Span checking

- Insulated sensor rod option for unmatched performance in applications where water condensation is likely

- Integrated user interface with keypad and display for intuitive instrument set-up and use

- 0-100% or user scalable display, of assistance to plant operators wishing to manually scale the display to an approximate known dust level

MAIN APPLICATIONS

The DM210 is used to monitor emissions from the following types of processes:

- Quarrying eg Rotary Dryers, Roller Mills

- HEPA filters e.g. pharmaceutical/biomedical plant

- Coal Mill / Cement Mill/ Cement Kiln arrestment plant

- Humid applications eg Dryers, Calcinators

- Wood cutting & chipping plant

TECHNICAL SPECIFICATIONS

| TECHNICAL SPECIFICATIONS | |

|---|---|

| Measured parameters | Dust |

| Technology | Electrodynamic™ Probe Electrification |

| Measurement/Monitoring capability | 0-500 mg/m3 (Leak monitoring) |

| Stack/Duct diameter suitability | 0.5 to 8 m |

| Flue gas temperature | 250°C standard, 400°C option |

| Baghouse | YES |

| Cartridge Filter | YES |

| Ceramic Filter | YES |

| Coalescent Filter | YES |

| Cyclone | YES |

| Electrostatic Precipitator (ESP) | NO |

| Wet Electrostatic Precipitator (WESP) | NO |

| Wet Scrubber | NO |

| Sensor variants | 316 stainless, or fully insulted PTFE coated option for conductive dust or humid flue gas application (Sensor Probe) |

| QA checks | YES if required by the user or regulator. |

TECHNICAL DATA

| TECHNICAL DATA | |

|---|---|

| Measurement capability | 0-500 mg/m3 (Leak monitoring) |

| Sensor Variants | 316 stainless, or fully insulted PTFE coated option for conductive dust or humid flue gas application (Sensor Probe) |

| Stack Temperature Ranges | 250°C up to 400°C option |

| Functionality and QA Checks | Automatic zero and span |

| Data Output | RS485 (Modbus) output to Controller |

| Air Purge | option |

| Enclosure Protection Rating | IP65 die-cast aluminium Enclosure |

APPROVALS & CERTIFICATIONS

- UKEX/ ATEX / IECEx Dust Zones 20, 21, 22

- US EPA MACT Compliant