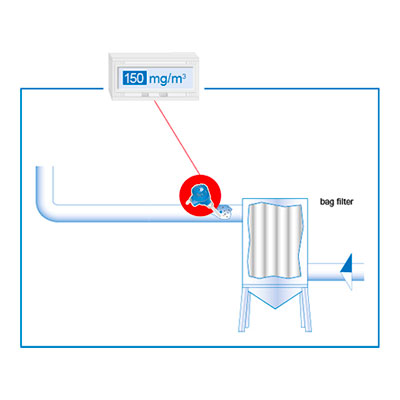

Provides continuous measurement values for dust concentration as a trend signal or absolute values

The ProSens has been specially developed to carry out reliable dust measurement on clean sides after filters.

The measuring device provides measurement values for dust concentration, either as a trend signal or as absolute values (after calibration) for emission measurement.

- Brand

- FEATURES & BENEFITS

- MAIN APPLICATIONS

- TECHNICAL SPECIFICATIONS

- TECHNICAL DATA

- MOUNTING & INSTALLATION

- VIDEO

FEATURES & BENEFITS

- Continuous, precise and reliable dust quantity measurement (mg/m3)

- Dust measurement possible in large channel diameters

- Output of dust concentration as absolute value

- ATEX-certified

- Measurement of dust concentration at high temperatures or harsh environment

- Trend signal or absolute value

MAIN APPLICATIONS

ProSens is used for:

- trend measurement in any dust channel

- exact measurements even with large channel diameters

- applications in explosion hazard zones (GasEx-Zone 1, DustEx-Zone 20)

- the measurement of dust concentration even at high temperatures or/and in harsh environment in various industries such as: Steel, Chemistry, Food, Cement, Minerals, Pharma

TECHNICAL SPECIFICATIONS

- Output: absolute value in mg/m3

- For exact measurement even with large channel diameters

- Measurement of dust concentration even at high temperatures

TECHNICAL DATA

| SENSOR TECHNICAL DATA | |

|---|---|

| Measuring objects | Particles in the gas flow |

| Measuring range | From 0.1 mg/m³ |

| Process temperature | Standard: 150 °C; optional: max. 500 °C |

| Pressure | Max. 2 bar (Optional: up to 25 bar) |

| Flow speed | Min. 4 m/sec |

| Humidity | 95 % rel. hum. or less (non-condensing) |

| Measuring principle | Electrodynamic technology |

| Ambient temperature | -20…+ 60 °C |

| Sensor rod | Material: stainless steel; length: 500 / 1000 mm |

| Housing | Aluminium |

| Protection type | IP 66; ATEX: cat. 1/2 GD |

| Electric connection | Connection room DIN M 20 |

| Measurement value alarm relay output |

Relay with switching contact Max. 125 V/AC, 2 A Not for EX-devices Cat. 1 and 2 |

| Weight | Approx. 1.5 kg |

| TRANSMITTER TECHNICAL DATA | |

|---|---|

| Power supply | 24 V DC ±10 % |

| Power consumption | 20 W / 24 VA |

| Protection type | IP 40 to EN 60 529 |

| Ambient operating temperature | -10 … +45 °C |

| Dimensions (W x H x D) | 23 x 90 x 118 mm |

| Weight | Approx. 172 g/td> |

| DIN rail fastening | DIN 60715 TH35 |

| Connection terminals cable cross-section |

0.2-2.5 mm2 [AWG 24-14]/td> |

| Current output | 1 x 4 … 20 mA (0 … 20 mA), load < 500 Ω |

| Interface | ModBus RTU (RS 485) / USB/td> |

| Pulse output | Open collector – max. 30 V, 20 mA |

| Relay contact | Max. rated load: 250 V AC Max. peak current: 6 A Max. rated load 230 V AC: 250 VA Max. breaking capacity DC1: 3/110/220 V: 3/0.35/0.2 A Min. switching load: 500 mW (10 V / 5 mA)/td> |

| Data backup | Flash memory |

MOUNTING & INSTALLATION

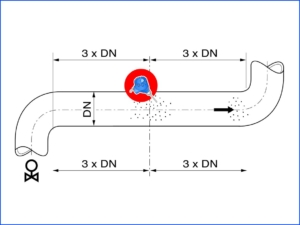

The ProSens can be installed in metal channels and pipelines.

The installation should take place away from any curves and other inserts such as flaps and valves.

The distance between the sensor rod and inserts in the channel should be at least 3 times the channel diameter in every flow direction.

Non-metallic channels must be sheathed using a metal sleeve, a metal foil or a close-mesh metal grid over a length of at least 5 times the channel diameter. After determining the installation location, a hole must be drilled in the channel wall to insert the welding casing flush. The casing is now welded into place vertically to the channel. The sensor rod is then inserted in this and fastened with a fixing screw. The length of the sensor rod should at least 1/3 and at most 2/3 of the channel diameter. It can be shortened to the respective optimal length (up to 70 mm) without a problem.