Flow-through sampling where you want it

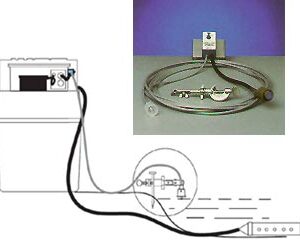

The Teledyne ISCO high temperature flow-through chamber makes “dipper” type samplers obsolete, and is ideal for large treatment plants with multiple sampling points spread over a large area. This device allows you to eliminate time-consuming trips to retrieve samples from remote monitoring points. By installing flow-through chambers on transfer lines from monitoring points within your plant, you can collect all your samples in one convenient, central, sheltered location.

With the “stinger” probe, samples are always collected from the middle of the flow stream, allowing you to use a much stronger pump to circulate the sample to the chamber. The Teledyne ISCO flow chamber can accommodate flows of up to 150 GPM (6.3 liters/second). By increasing the flow rate, you reduce maintenance and cleaning – and there’s no flow stoppage as required with a dipper sampler and weir structure.

- Brand

- STANDARD FEATURES

- MAIN APPLICATIONS

- SPECIFICATIONS

STANDARD FEATURES

Use with any Teledyne ISCO sampler and bottle configuration

High flow rate – up to 150 GPM

Attachable parameter probe ports

MAIN APPLICATIONS

Save time and money by eliminating sample retrieval trips. Collect all your samples in one convenient, indoor location

Monitor parameters, too. Use additional chambers to monitor pH, DO, or other parameters.

OPTIONS & ACCESSORIES

CPVC or PEEK stinger probe

Chamber mounting bracket

SPECIFICATIONS

Flow-Through Sample Chamber

| Description: | Self-flushing flow chamber with probe for mid-stream collection of representative samples. |

|---|---|

| Materials: | Chamber body – ABS; stinger probe – CPVC or PEEK |

| Length: | 8 inches (20.3 cm) |

| Inlet: | 2 inches (5.1 cm) |

| Outlet: | 3 inches (7.6 cm) |

| Minimum Flow Rate: | 10 GPM (0.4 liters/second) |

| Maximum Flow Rate: | 150 GPM (6.3 liters/second) |

| Maximum Line Pressure: | 15 psi (1 Bar). For pressures exceeding 15 psi, contact the factory for pressurized line sampling information. |