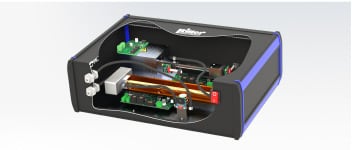

Analyze up to 4 different gases in only one table-top casing simultaneously with 3 modules. The modular components enable flexible adaptation of the measuring system to individual measuring tasks.

- Brand

- Modular sensor design

- Configurations and measurement ranges

- Table of Detection Limits

- Available arrangements

Modular sensor design

Analyse up to 4 different gases plus pressure and humidity simultaneously In order to adapt gas analysis as flexibly as possible to individual measurement tasks, the single components were designed modularly. This resulted in a »modular system« in which the various photometric components such as detectors, emitters, measuring sample cell, etc. can be assembled user-specifically.

With this sophisticated sensor design, customer-specific applications can be realized without needing a completely new development. The modularity makes replacement and maintenance considerably easier when servicing is required. In contrast to this design, common completely glued gas sensors can only be replaced as a complete unit thus generating high follow-up costs (total cost of ownership) in case of maintenance. Optionally, modules can also be equipped with a sensor for oxygen, pressure and humidity.

Have a look at our brand new RITTER MultiGas Sensors brochure!

Configurations and measurement ranges

| Measuring ranges / Full scale value (F.S.) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 Vol.% | 50 Vol.% | 30 Vol.% | 20 Vol.% | 10 Vol.% | 5 Vol.% | 1 Vol.% | 5,000 ppm | 2,000 ppm | 1,000 ppm | 500 ppm | 300 ppm | 100 ppm | 50 ppm | 10 ppm | |

| CO2 | |||||||||||||||

| CO | |||||||||||||||

| N2O | |||||||||||||||

| CH4 | |||||||||||||||

| CnHm* | |||||||||||||||

| CF4 | |||||||||||||||

| SF6 | |||||||||||||||

| H2O | Measurement ranges on request | ||||||||||||||

| O3 | |||||||||||||||

| CL2 | |||||||||||||||

| H2S | |||||||||||||||

| SO2 | |||||||||||||||

| NO2 | |||||||||||||||

| NO | |||||||||||||||

Infrared module NDIR Ultraviolet module NDUV

* Calibration with Propane

Table of Detection Limits

| Detection Limits / % of Full Scale Value (F.S.) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 Vol.% | 50 Vol.% | 30 Vol.% | 20 Vol.% | 10 Vol.% | 5 Vol.% | 1 Vol.% | 5,000 ppm | 2,000 ppm | 1,000 ppm | 500 ppm | 300 ppm | 100 ppm | 50 ppm | 10 ppm | |

| CO2 | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.3% | < 0.3% | |||

| CO | < 0.2% | < 0.2% | < 0.2% | < 0.2% | < 0.2% | < 0.2% | < 0.2% | < 0.3% | < 0.5% | < 0.5% | |||||

| N2O | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.3% | |||||||

| CH4 | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.3% | < 0.5% | ||||||

| CnHm* | < 0.1% | < 0.1% | < 0.1% | < 0.2% | < 0.2% | < 0.2% | < 0.2% | < 0.5% | < 0.5% | ||||||

| CF4 | < 0.2% | < 0.2% | < 0.2% | ||||||||||||

| SF6 | < 0.1% | < 0.1% | < 0.1% | < 0.2% | < 0.5% | < 0.3% | < 0.3% | ||||||||

| H2O | Measurement ranges on request | ||||||||||||||

| O3 | < 0.1% | < 0.1% | < 0.1% | < 0.2% | < 0.5% | < 0.5% | < 0.5% | ||||||||

| CL2 | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.2% | < 0.5% | ||||||

| H2S | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.2% | < 0.5% | |||||||||

| SO2 | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.1% | < 0.5% | < 0.5% | < 0.5% | ||||

| NO2 | < 0.1% | < 0.1% | < 0.1% | < 0.2% | < 0.2% | < 0.5% | < 0.5% | < 0.5% | |||||||

| NO | < 0.1% | < 0.1% | < 0.1% | < 0.2% | < 0.2% | ||||||||||

Definition of Detection Limit

The Detection Limit is the smallest measurement value which can be obtained with a specific uncertainty. This uncertainty includes the resolution, noise and stability of the gas sensor for a specific gas and specific measurement range. For evaluation of the detection limit value, several single measurements are taken at the identical measurement conditions. With the obtained single measurement results the standard deviation “Sigma” (σ) is calculated. The values given in the table equal the triple amount of Sigma.

Available arrangements

| Arrangement | Sensor 1 (*) | Sensor 2 (*) | Sensor 3 (*) | Options / Additional sensors (**) | |||

|---|---|---|---|---|---|---|---|

| MultiGas mono 1 Sensor + options |

1.1 |

CO2 CO N2O CH4 CnHm* CF4 SF6 H2O

|

O2 | P | H | ||

| 1.2 |

O3 CL2 H2S SO2 NO2 NO

|

O2 | P | H | |||

| MultiGas duo 2 Sensors + options |

2.1 |

CO2 CO N2O CH4 CnHm* CF4 SF6 H2O

|

CO2 CO N2O CH4 CnHm* CF4 SF6 H2O

|

O2 | P | H | |

| 2.2 |

O3 CL2 H2S SO2 NO2 NO

|

O3 CL2 SO2 NO2

|

O2 | P | H | ||

| 2.3 |

CO2 CO N2O CH4 CnHm* CF4 SF6 H2O

|

O3 CL2 SO2 NO2

|

O2 | P | H | ||

| MultiGas trio 3 Sensors + options |

3.1 |

CO2 CO N2O CH4 CnHm* CF4 SF6 H2O

|

CO2 CO N2O CH4 CnHm* CF4 SF6 H2O

|

CO2 CO N2O CH4 CnHm* CF4 SF6 H2O

|

O2 | P | H |

| 3.2 |

CO2 CO N2O CH4 CnHm* CF4 SF6 H2O

|

O3 CL2 SO2 NO2

|

O3 CL2 SO2 NO2

|

O2 | P | H | |

| 3.3 |

SO2

|

NO2

|

NO

|

O2 | P | H | |