The intensity of the current debates surrounding the restrictions on the use of perfluorinated and polyfluorinated alkyl substances (PFAS) illustrate the relevance of this group of substances. The industrially produced organic compounds are very resistant and many everyday objects and specialized products, for example in medical technology, would not be able to do without them. However, the residues accumulate worldwide in plants, soil, water and living organisms, and they are considered hazardous to health.

The PFAS Sampling Kit contains:

- Stainless steel suction strainer (3/8”, low profile)

- LDPE suction line (3/8”, 7.6 m)

- Silicone pump and outlet hose (3 m)

- HDPE bottles in various sizes

- ProPak kits: 100x ProPak disposable sample bags made of LDPE, with corresponding holders and caps

- Nitrile gloves, Liquinox cleaning fluid, 4 HDPE bottles for blanks, PFAS-free water, instructions

In view of the existing and expected new regulations, the monitoring of PFAS is becoming increasingly important. The mobile automatic samplers from Teledyne ISCO have been tested for their suitability for PFAS sampling and optimized with regard to the materials used.

Teledyne ISCO has produced a guide to best practice for PFAS sampling. Further information can be found here: https://www.teledyneisco.com/en-us/Water_/Pages/PFAS.aspx

- Brand

- Wastewater Based Surveillance

- How-To

- Grab vs. Automated Sampling

- PFAS Sample Collection Kit

- How To Videos

- Documents

Wastewater Based Surveillance

Wastewater Based Surveillance (WBS)

The use of wastewater sampling to detect pathogens, illicit drugs and other chemicals reached new heights when it was applied to detect SARS-COV-2, the coronavirus that causes COVID-19. On university campuses, for example, dormitory wastewater is tested to determine areas of breakout to confine the spread.

Testing water and wastewater for PFAS, however, involves extreme challenges. This is due to the widespread use of PFAS (there are thousands of PFAS chemicals, and they’re used in everything from toothpaste tubes to non-stick cookware and food containers, to water-repellent clothing and personal hygiene products); their ubiquitous nature in the air, water, soil and animals; and the fact they take years to break down.

How-To

A How-To for Sampling Water & Wastewater to Detect PFAS

PFAS can be detected in trace amounts in water and wastewater, but obtaining an accurate assessment is a challenge due to the widespread nature of the chemicals. Exacting steps must be taken before, during and after samples are obtained to ensure they are not compromised.

As experts in water and wastewater sampling and flowrate measurement for more than 60 years, Teledyne ISCO is uniquely qualified to assist in determining and implementing best practices that take much of the guesswork, wasted time, unnecessary expenses, and inaccurate analysis due to compromised samples out of the equation.

For more detailed information specific to your application, contact our Water Product Support team at iscowatersupport@teledyne.com or in the United States, toll-free at 866-209-6174.

Equipment Choices/Material Selection

PFAS sampling is conducted similarly to other sampling projects. Due to the prevalence of PFAS in our environments and the extremely small quantitative measurements (0.02 ppt) in the EPA guidelines, the potential for cross-contamination is significant. Therefore, greater care is required to avoid compromising the quality of the collected water sample.

Sources of contamination

Avoid the following before and during sampling or while at the sampling site. While not an exhaustive list, these points demonstrate the prevalence of PFAS and the care that must be taken.

Personal sources of contamination: soaps, shampoos, insect repellants, sunscreen, moisturizing lotion, cosmetics, some toothpastes

Clothing washed with fabric softeners or marked as stain-resistant/waterproof

Fast food containers/packaging, food or drink in sealed packages (e.g., juice boxes)

Materials that are NOT in direct contact with the sample but should be avoided include: GPS receivers, notebooks, clipboards, etc.

Please note that PPE could contain PFAS. However, never compromise safety for the sake of eliminating PFAS material. If there is no equivalent PFAS-free option available, document the use of such and use a blank sample to establish a baseline presence of PFAS with the equipment and the exposure potential.

Materials to use or avoid in sampler parts

At the top of the list of materials that must be avoided, DO NOT USE PTFE or FEP tubing or any tubing that contains fluoride for suction line or any part of the sampler equipment. Use high-density polyethylene (HDPE) sample collection bottles. Avoid low-density polyethylene (LDPE) unless verified to be PFAS-free.

Approved Materials

- Stainless steel (for strainers, tubing couplers, and bulkhead fittings)

- Vinyl (for suction lines)

- Silicone (for pump tubing). See the Teledyne ISCO poster: PFAS Applications-Study on Tubing)

- HDPE or polypropylene (PP) for collection bottles

Materials to avoid or use with caution

- LDPE (unless PFAS-free verified)

- Glass (unless PFAS-free verified)

- Teflon or related materials

- Any fluoropolymer materials

- Gel-Paks

Equipment considerations

- Sampling equipment should be dedicated to sampling PFAS.

- Decontamination is a MUST due to the sensitive nature and cross-contamination threat. This is often accomplished by a thorough rinse of the sample lines using known PFAS-free water.

- Communicate with your analytical laboratory and appropriate regulatory agency for their specific decontamination recommendations.

Grab vs. Automated Sampling

Grab samples increase the risk of cross-contamination due to the direct human contact with the act of collecting the sample. Automated sampling results in consistent samples and eliminates variances that can impact sample integrity.

Sampling with Grab Dipper

Pros:

- Lower Initial Cost

Cons:

- Increased Risk of PFAS Contamination

- Less Hygienic

- Time-Consuming

- Variation in Sample Collection

- Represents Singular Moment in Time

Sampling with Automatic Sampler

Pros:

- Hygienic

- Quicker

- More Consistent Sampling

Cons:

- Initial Cost

Automatic Sampler Factors

Composite sampling is most common. Time-paced is common but there are those who flow-pace as well, assuming there is a flowmeter in place to perform that function.

Blanks

Prepare three types of equipment blanks before and after sample collection using PFAS-free deionized water:

- Equipment Rinse Blank

- Field Blank

- Trip Blank

These blanks ensure sampling components are not contributing to false readings or elevated PFAS detection. Consult specific guidelines for procedures on equipment cleansing and blank preparation.

Click here to find details on equipment cleansing and taking blanks.

Programming approaches

- Could one day be regulatory driven, but currently, normal approaches for programming are acceptable.

- Time paced: common is one sample every 15 minutes for 24 hours

- Flow paced: It is common to design a program that will collect 96 samples based upon average daily flow volume over 24 hours (Note: Flow pacing is not suitable for applications that have a wide range of daily volumes.)

The future: Regulatory Considerations

The EPA is expected to develop more comprehensive guidelines for PFAS as new toxicity assessments are published. While current limits are guidelines rather than regulations, the extremely low recommended levels (0.02 parts-per-trillion) suggest that future regulations could be stringent. As PFAS research evolves, sampling and detection methods will likely become more refined, necessitating ongoing environmental media updates to best practices.

PFAS Sample Collection Kit

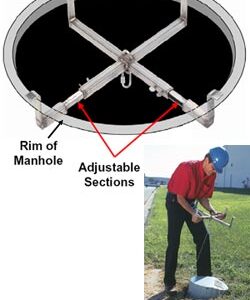

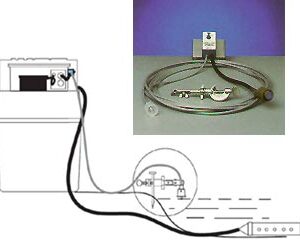

Special collector kit for PFAS Sample Collection

The kit includes Category 1 items that come directly in contact with samples, such as strainer, suction line, pump tube, bottles to prepare blanks, and sampler collector. The kit also includes some of Category 2 items that do not come in contact with the sample, but are used in the sampling process.