For Teledyne ISCO 6712, BLZZRD, Avalanche, and 5800

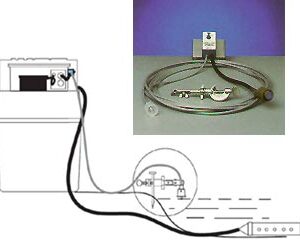

This accessory was developed to allow sampling from liquid sources with pressure ratings between 10 and 300 psi. Initially, a stainless steel pressure reduction valve decreases source pressure to an acceptable level (10 psi).

Special software (required as an option for 6712, BLZZRD and Avalanche samplers), activates an electric ball valve – via the valve interface – directing liquid to the collection bottle during forward pumping. The ball valve also allows any liquid remaining in the section of line between the ball valve and the sampler to be purged prior to the next sample being drawn.

Note: Photo shows purge line lower than desired. Optimum purging occurs when sampler outlet is higher than connection to valve.

- Brand

- STANDARD FEATURES

- MAIN APPLICATIONS

- SPECIFICATIONS

STANDARD FEATURES

-

Components are mounted on an aluminum backing plate that also serves as a mounting bracket.

-

Plug-in connection to 120 or 230VAC outlet.

-

Pressure reduction valve has standard ½-inch NPT (female) inlet fitting for connection to user-supplied plumbing.

MAIN APPLICATIONS

- Potable water

- Filtered surface water

- Filtered waste water

- Industrial processed liquids

OPTIONS & ACCESSORIES

-

Complete pressurized sampling system for 6712/Avalanche/BLZZRD samplers. Includes required software option.

-

for 120 VAC – PN 68-5304-001

-

for 230 VAC – PN 68-5304-007

-

-

Complete pressurized sampling system for 5800 samplers.

-

for 120 VAC – PN 68-5304-006

-

for 230 VAC – PN 68-5304-005

-

SPECIFICATIONS

Pressurized Line Accessory

| Mounting Plate Size (HxW): | 12 x 24 inches (30 x 60 cm) |

|---|---|

| Weight: | 18 lb (8.2 kg) |

| Power: | 120V or 230V AC/60 Hz |

| Maximum inlet pressure: | 300 psi |

| Minimum inlet pressure: | 10 psi |

| System enclosure rating: | NEMA 4X |

| Operating temperature: | 32 to 140 °F (0 to 60 °C) |

| Maximum liquid temperature: | 145 °F (62.77 °C) |