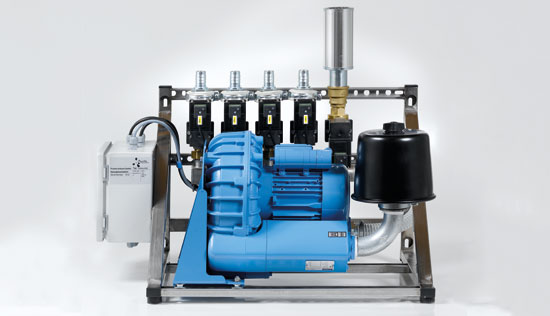

No matter how much gas will be produced, AwiDESULF monitors continuously and regulates itself.For biogas plants with a capacity of 300 / 500 Nm3/h

- Brand

- OVERVIEW

- SPECIFICATIONS

OVERVIEW

SPECIFICATIONS

MICROBIOLOGICAL DESULPHURISATION

| GENERAL DATA | AWIDESULF 3001 | AWIDESULF 5001 | AWIDESULF 10001 |

Volume biogas/h2 3 3 3

| OPERATION CONDITIONS | |

| Ambient temperature | 5 – 40 °C |

| Ambient humidity | 0 – 80 % relative humidity |

| Protection type | IP 55 |

| POWER SUPPLY | |

| Rated voltage | 220 – 240 VAC |

| Rated power 50Hz / 60Hz | 0,37 kW / 0,37 kW 0,75 kW / 0,90 kW 1,50 kW / 1,80 kW |

| Power supply | solenoid valves are powered by Awite gas analysis system the compressor is powered on-site |

| PROCESS CONNECTION | |

| Number of air supply points | 1 – 4 |

| Connection point of air supply | flexible or solid plastic pipe 1“ and connection with G1“ external thread on customer side |

| Pipe length2 | ≤ 100 m |

| PROCESS CONTROL3 | |

| Automatic control of air supply using a combination of PI-controller and a major FuzzyLogic | |

| Control range in automatic mode between 0 to 1 % oxygen, de-

pending on the measured hydrogen sulfide concentration |

|

| Monitoring of the upper limit of 3 % of oxygen | |

| DISPLAY AND OPERATION3 | |

| Panel-PC | 7“ TFT touch panel/800×480 |

| SOFTWARE FEATURES3 | |

| Display of measurement history | graphic/tabular |

| Extensive data storage | 4 GB microSD card |

| SAFETY MECHANISM | |

| Non-return valve behind compressor |

Motor protection switch with feedback

More From Avensys

More Services

Our certified engineers and technicians can intervene from the initial consultation and planning stages, throughout the life of instruments and systems.